Modern manufacturing relies heavily on accuracy, speed, and seamless coordination between departments. As customer expectations evolve, businesses need tools that help them manage complex orders with minimal errors. This is where product configurator software becomes essential. It allows teams to integrate data, automate workflows, and eliminate the guesswork that often slows down production and quoting. By creating a system where information flows smoothly from sales to engineering to the factory floor, manufacturers can work smarter, deliver faster, and provide a more reliable customer experience.

A Unified Approach to Custom Orders

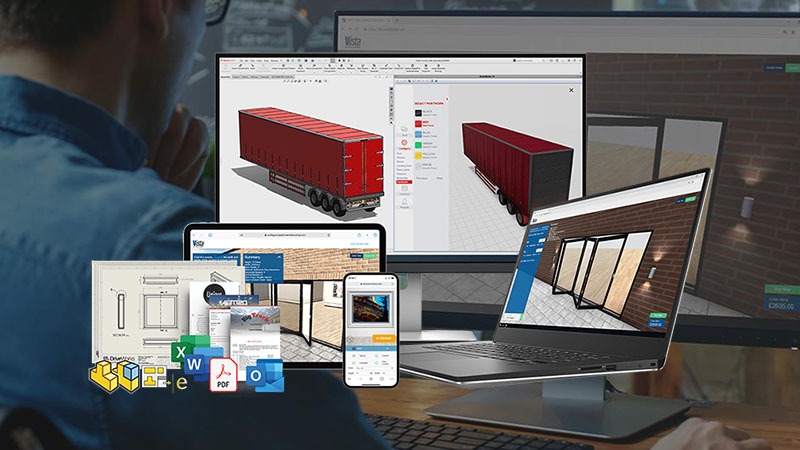

Manufacturers offering customizable products often deal with endless variations in size, color, material, and features. Managing these options manually can lead to miscommunication or inaccurate orders. Product configurator software brings all these possibilities into a single guided interface. Customers or sales teams can mix and match options while the system ensures compatibility and accuracy. This unified approach removes confusion and keeps everyone working from the same ruleset, so no detail gets overlooked.

Once the configuration is complete, the software instantly generates accurate specifications. This eliminates the old method of manually creating paperwork or relying on multiple systems. Everything is captured in real time, allowing the next stage in the process to begin without delay.

Faster and More Accurate Quoting Processes

Quoting has traditionally been one of the biggest bottlenecks in manufacturing. Sales teams often wait for engineering approval, costing valuable time. With product configurator software integrated into the workflow, quotes can be generated instantly. The system calculates pricing based on selected features, materials, and production rules, ensuring consistent and transparent pricing.

This technology makes the quote process go faster and builds trust with customers. When clients receive detailed quotes quickly, they are more likely to move forward with the order. Automated quoting also reduces the risk of underpricing or miscalculating costs, helping companies protect their profit margins while staying competitive.

Streamlined Communication Between Departments

Another major benefit of this technology is improved communication. In many organizations, information bounces between sales, engineering, and manufacturing teams, creating opportunities for delays and errors. Configurator systems eliminate this challenge by converting customer selections into clear production data.

Engineering teams receive accurate models and documentation without needing to redo work or verify details. Manufacturing receives clear instructions aligned with production capabilities. This creates a smooth workflow where each department stays informed and aligned, reducing confusion and costly rework.

Enhanced Efficiency on the Production Floor

Once orders reach the factory floor, precision is everything. Automated configurations help generate accurate bills of materials and assembly instructions. Production teams know exactly what needs to be built, the materials required, and the correct sequence of steps. This improves workflow efficiency and allows teams to use time and resources more effectively.

Automated instructions also support better inventory management. The system can identify material needs early, helping companies avoid shortages or overstock situations. This leads to better planning and lower operational costs.

A Scalable Solution for Growing Businesses

One of the greatest strengths of configurator technology is scalability. Whether a company handles a few custom orders each week or thousands per month, the system adapts to demand. As a business expands its product line or enters new markets, configurators can be updated with new rules, pricing structures, or design features.

This flexibility helps companies grow without sacrificing speed or accuracy. It also allows teams to spend more time focusing on innovation and customer service instead of dealing with manual administrative tasks.

Final Thoughts

In a world where customers expect fast responses and tailored solutions, manufacturers need tools that make operations simpler and more efficient. Product configurator software provides exactly that by integrating data, automating key processes, and improving communication across teams. It streamlines manufacturing, accelerates quoting, and reduces the risk of errors, all while supporting long-term growth. Adopting this technology is a smart move toward a more connected and automated future for companies that want to be more productive and provide uniform quality.